Cleanrooms and associated controlled environments

Published date: |

|

Modified date: |

|

When David Bowie sang ‘Is there life on Mars?’ he was probably not thinking about bacteria. Bacteria lives in almost all spaces in existence and its presence can pose a significant problem when trying to keep an environment contained. One such industry that relies on this cleanroom control is the aerospace sector. Avoiding contamination is vitally important as anything that goes into space needs to be as free from contaminants as possible - both to to keep sensors and instruments clean and to prevent the introduction of bacteria into new, off-world environments.

When David Bowie sang ‘Is there life on Mars?’ he was probably not thinking about bacteria. Bacteria lives in almost all spaces in existence and its presence can pose a significant problem when trying to keep an environment contained. One such industry that relies on this cleanroom control is the aerospace sector. Avoiding contamination is vitally important as anything that goes into space needs to be as free from contaminants as possible - both to to keep sensors and instruments clean and to prevent the introduction of bacteria into new, off-world environments.

Keeping rockets germ-free

Making sure that rockets are free of contaminants is crucial to the success of space exploration. Unfortunately, it’s no easy task as the human body is far from sterile. On one square inch of a human hand, you will find around 10,000 bacteria. The challenge for those who work in cleanroom environments is to keep these contaminants under control.

The process for keeping a rocket germ-free is strict. For example, a joint project between NASA and the European Space Agency saw the launch of the Solar Orbiter spacecraft in February 2020, in which the spacecraft was made and stored in a cleanroom prior to launch.

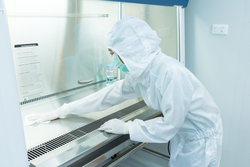

Entering a cleanroom is a multi-stage process. Those wishing to enter will need to use a special machine for cleaning shoes, wear a cloth suit and shoe covers, additional knee-high foot coverings and rubber gloves, as well as a cloth hood and face covering. You would also need to briefly stand in an air shower – an entryway system which blasts the body with high pressure air streams to help remove unwanted particles – before entering the clean space.

While these may seem like extreme measures, these precautions are necessary to ensure that spacecraft are kept as free as possible from contaminants; typically an entire spacecraft would be expected to have as many bacteria spores as you would find on a single human finger.

Which sectors use cleanrooms?

Aerospace is not the only sector to rely on cleanrooms. Any product or process which benefits from the control of airborne contamination will utilise cleanrooms, including microelectronics, pharmaceuticals, medical devices, healthcare and food.

A cleanroom controls for pollutants such as dust, aerosol particles, airborne microbes and chemical vapours, achieving a specified number of particles per cubic metre. Other environmental parameters such as temperature, humidity and pressure will also be controlled within the cleanroom.

To maximise control, High Efficiency Particulate Air (HEPA) filters are used to trap particles which are 0.3 micron or larger in size. In some cleanrooms, Ultra Low Particulate Air (ULPA) filters are used in addition to airlocks, showers and protective clothing.

How do you test a cleanroom?

Accurate testing of cleanrooms is essential in order to confirm that particles are present in the expected parameters. A revised international standard, BS EN ISO 14644-3:2019 Cleanrooms and associated controlled environments sets out test methods for these environments.

The standard covers test methods for the operation of cleanrooms and clean zones to meet air cleanliness classification, other cleanliness attributes and related controlled conditions. It covers performance tests for rooms with unidirectional and non-unidirectional airflow, in as-built, at-rest and operational states.

The test method guidance relates to recommended test apparatus and test procedures for determining performance parameters. In some tests, it may be suitable to use several different methods and apparatus to accommodate various end-use considerations.

What is new in the revised standard?

The standard has been revised from the previous 2005 edition. Clause B7 has been simplified and corrected to address concerns about its complexity and noted errors, guidance over the classification of air cleanliness by airborne particle concentration has been moved to a separate standard (BS EN ISO 14644-1), a new segregation test has been introduced and other test methods have been updated and expanded.

The entire text of the standard has also been revised and updated to make it more user-friendly.

Who can use the standard?

The standard can be used in many industries, including nanotechnology, aerospace, life sciences, optics, food, medical devices, healthcare, microelectronics and pharmaceuticals. It will be of use to people involved in cleanroom testing, quality assurance and quality control managers, design professionals and all those who work in or with cleanrooms.

The revised standard is available through the BSI online shop.

Click here to provide feedback