Health and safety in tunnelling in the construction industry

Published date: |

|

Modified date: |

|

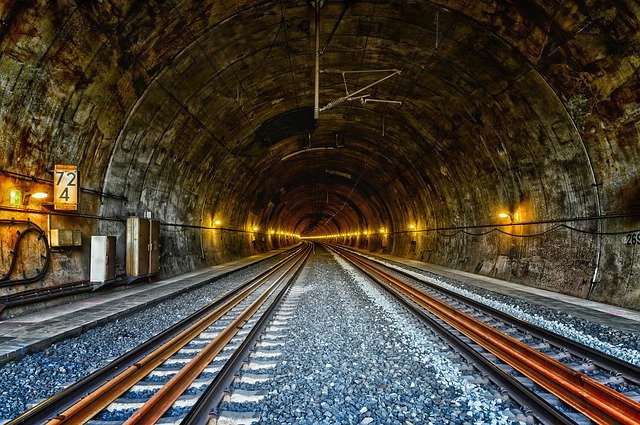

In densely populated areas, using space underground enables us to make the most of our resources. Today, the ground beneath our feet holds a number of things – for example transport lines, storage facilities and living opportunities.

In densely populated areas, using space underground enables us to make the most of our resources. Today, the ground beneath our feet holds a number of things – for example transport lines, storage facilities and living opportunities.

As a result, there is a continual demand for tunnels. Road and railway tunnels move people and goods every day. Without such infrastructure, the economy and society would feel the impact.

One of London's latest projects, the Thames Tideway Tunnel, spans 24 construction sites and will create a 25 km tunnel from west to east London. This will expand London's sewer network to cope with the increasing population and to significantly reduce sewage overflows into the river.

Tunnelling: a high-risk business

When precision planning, design and construction are matched with a meticulous approach to health and safety, any tunnelling project can be a success. However, the construction industry is well known for being one of the UK's highest-risk sectors.

Tunnels are unique; their design and construction are different from other structures. They have the same risks as surface construction does but within a confined space underground.

As a result, tunnelling projects require a robust standard that keeps health and safety front of mind throughout a project.

BS 6164:2019

BSI has published the revised standard BS 6164:2019, Health and safety in tunnelling in the construction industry – Code of practice, which takes into account advances in technology, techniques and equipment in the tunnelling industry, as well as health and safety legislation.

It is not a standalone document but depends heavily on the following:

- BS EN 16191:2014, Tunnelling machinery — Safety requirements;

- BS EN 12110:2014, Tunnelling machines — Air locks — Safety requirements; and

- the British Tunnelling Society Compressed Air Working Group's 'Guide to the work in compressed air regulations'.

These are all currently being extensively revised.

The standard also refers to the International Tunnelling Association/British Tunnelling Society Compressed Air Working Group Report 10, 'Guidelines for good working practice in high pressure compressed air'.

What's changed in BS 6164:2019?

There are numerous changes in the revised standard. They arise from legislative changes within Europe, lessons learnt since the 2011 revision was published, changes in tunnelling practice over the past decade, advances in technology that allow for improvements in health and safety practice, and as a consequence of advances in technology creating new hazards. Finally, some content was in need of a general edit and rationalization.

Legislative changes since 2011 include the classification of respirable crystalline silica as a human carcinogen, prompting more rigorous guidance on reducing emissions at source and dust control primarily through extraction ventilation.

Clause 7 has been extensively rewritten but with few technical changes, to reflect the revised clause title 'Excavation and control of ground movement'. Soft ground and hard rock tunnelling is covered, as well as pipe and box jacking. The guidance on ground improvement techniques, including freezing and grouting, has been moved to Clause 9. The guidance on plant and equipment safety along with materials handling has been rationalized, and a general edit of this clause has been undertaken. Guidance on all methods of materials handling has been brought together in Clause 23, and guidance on plant and equipment safety, including hired plant, is set out in Clause 24. The requirements for vehicle fire suppression and for the use of surface construction plant underground have been comprehensively addressed.

A major change in tunnelling technology just starting to appear in UK tunnelling is the use of high pressure compressed air techniques for cutterhead interventions. Guidance on the technique is now included in the standard. Shafts are an often forgotten but vitally important aspect of tunnelling. The past decade has seen significant increases in shaft size and depth along with changes in construction methods. As a consequence, Clause 20 on shafts has been considerably extended to address these changes. A formal definition of when a shaft should be considered a confined space has been included. The basic use of electricity on tunnel sites has not changed, however. With ever larger tunnel boring machines being used, the power demand on-site has grown considerably. Consequently, the clause on electrical safety has been revised to reflect current electrical power engineering practice.

How has the standard improved?

Lessons learnt since 2011 have led to the inclusion of extensive recommendations on design checking. Guidance is given on the involvement of clients in determining the scope and nature of checks to be made. The category of check to be made should be determined on the basis of failure risk. The competence of the checker is addressed, and the checker is now required to certify the constructability as well as the safety of the design. Guidance is given for the first time on resolving disputes arising from the design check process. Guidance is also given on exclusion zones in conventional tunnels being built using sprayed concrete lining.

In addition, advances in technology are resulting in instruments becoming available for the real-time monitoring of dust concentrations and their composition. This comes at a time when there is concern that control based on long-term average exposure does not adequately reflect the risk from fluctuating dust exposure, particularly in sprayed concrete lined tunnels. Recommendations are now made for control of dust exposure to be based on real-time monitoring against short-term exposure limits, making use of the advances in technology. Since exposure to vehicle exhaust is also of growing concern and similar monitoring instrumentation technology can be used for real-time monitoring of diesel particulate matter (DPM), guidance is included in the standard on control of exposure to DPM.

As part of the general drive to reduce dependence on fossil fuels and also exposure to exhaust emissions, there is a resurgence in the availability of battery-powered vehicles for underground use. However, lead acid batteries are being replaced by battery technologies utilizing hazardous substances such as lithium and various heavy metals. The hazardous nature of such batteries, including the highly toxic emissions given off in a fire, along with the difficulty of extinguishing such fires, has been addressed.

Find out more

If you're involved in tunnelling at any stage, this is a good standard to review and use in your activities.

The recommendations in this standard are not intended to apply to the construction of shafts or tunnels for the purpose of mineral extraction.

BS 6164:2019 makes recommendations and gives guidance on health and safety practices in shaft sinking, tunnel construction, cut-and-cover tunnelling, immersed tube tunnels, and other underground construction, maintenance, renovation and repair.

Find out more today.

This article has been guest-written by an industry author

Dr Donald Lamont is a former head of tunnel engineering for the Health and Safety Executive and is now a director of Hyperbaric and Tunnel Safety Ltd. He is an internationally recognised specialist in tunnelling health and safety and has been chairman of the BSI committee responsible for the last three revisions of BS 6164. He is also active in CEN and ISO standards work.

Click here to provide feedback